I. Kinetics and reactor modeling,

analysis, and optimization

II. Modeling of large-scale processes

III. Computational fluid dynamics

model

I. Kinetics and reactor modeling, analysis,

and optimization

l Development

of catalytic reaction mechanism

l Kinetics

modeling with parameter estimation

l Reactor

modeling and analysis (lab- and pilot-scale, micro-reactors)

l Process

modeling and optimization

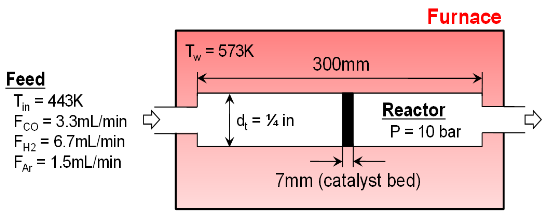

<Fig.

1> Scheme of a lab-scale catalytic reactor for kinetic modeling research.

Catalytic

kinetic models developed in our lab

Fischer-Tropsch synthesis (Fe- and Co-based)

Mixed reforming

(Steam/CO2)

Methanol synthesis

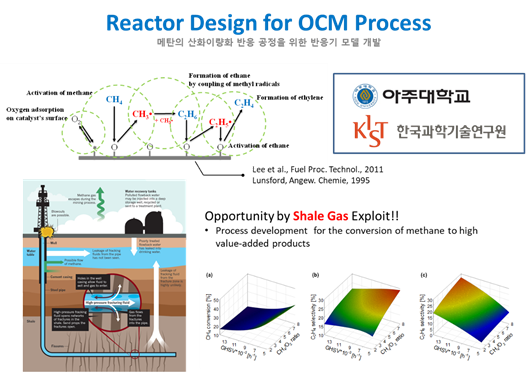

Oxidative coupling

of methane

Catalytic

esterification of butyric acid and n-butanol

Hydrocracking (upgrading

for BTL synthetic fuels)

Furfural production

from D-xylose

Hydrogen production

from EG reforming

Deoxygenation of

oleic acid for biofuels

Ketonization reaction

Ethylene

oligomerization

Hydrogenation of

furfural to 2-MF

Condensation of 2-MF

Hydrodeoxigenation

Hydrodechlorination of TCM

Water-gas-shift

reaction

etc

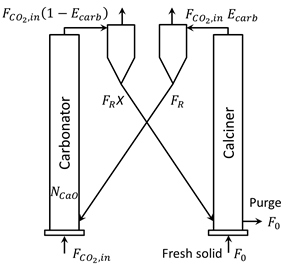

II. Modeling of large-scale processes

l Pre-combustion

CCS with membranes (collaboration with KIER)

l

Modeling of a fluidized bed reactor for

dry-based CCS process

l

Modeling of a MeOH synthesis process (mixed

reforming + MeOH synthesis)

l

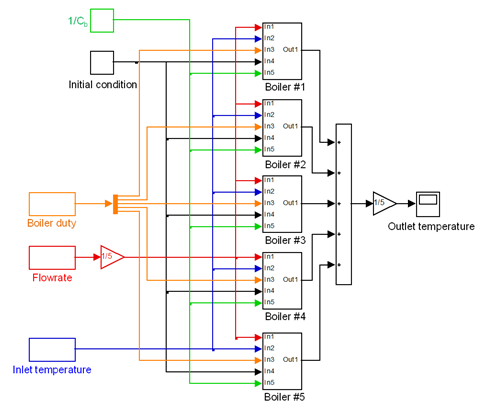

Modeling and control (MPC) of a thermal plant

in a district heating network

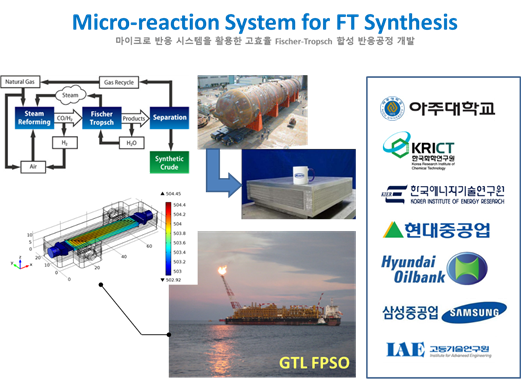

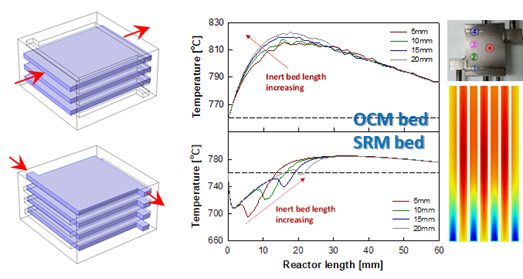

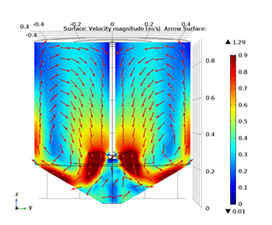

III.

Computational fluid dynamics model

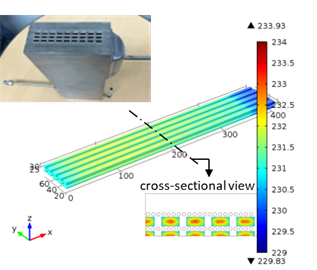

l Micro-reactor

for Fisher-Tropsch synthesis

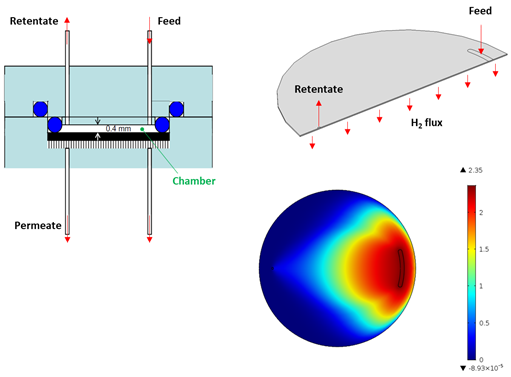

l Hydrogen

permeable membrane module

l Thermal

control reactor for coupled exothermic and endothermic reactions

l Hydrodynamic

behaviors of Ag-powder reactor/Fluidics for homo-mixer system

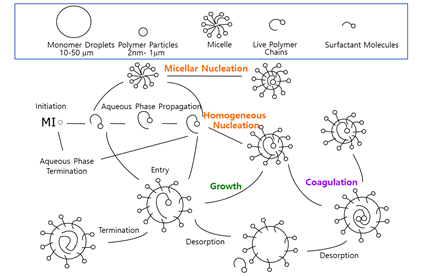

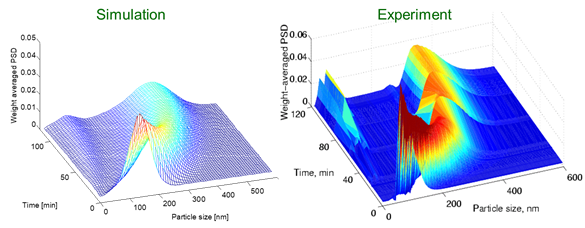

l Kinetics

for solution MMA/MA copolymerization

l Kinetics for emulsion

polymerization

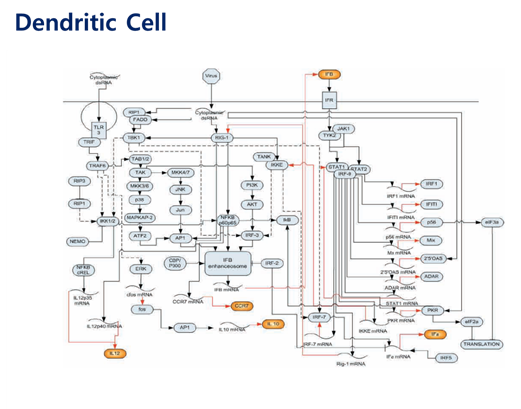

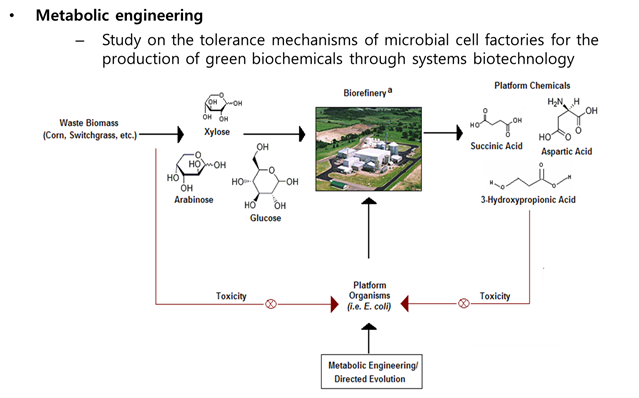

l Metabolic

flux analysis

l Modeling

of signal transduction pathways